Macro Pad for 3DConnexion SpaceMouse Wireless

/Motivation

I was aware of CAD Mice, but always considered them a luxury and resited to urge to purchase one as I couldn't justify the hefty price tag. After using a work colleague’s SpaceMouse Compact, I bit the bullet and purchased an entry-level SpaceMouse Wirelessby by 3dconnexion. I was in love, and it dramatically changed the way I interact with CAD models.

The downside of purchasing a lower-end model was now I have to switch my hand between the SpaceMouse and keyboard to use the keyboard shortcuts I heavily relied on. I considered upgrading to a SpaceMouse Enterprise, but the hefty price tag and limited customizability made me want to design my own extension macro pad instead.

SpaceMouse Enterprise - Hefty price tag, and most buttons are not customizable

SpaceMouse Wireless - Only two macro buttons

Design

I started by marking on my desk where my fingers would naturally land if there was a macro pad next to the SpaceMouse

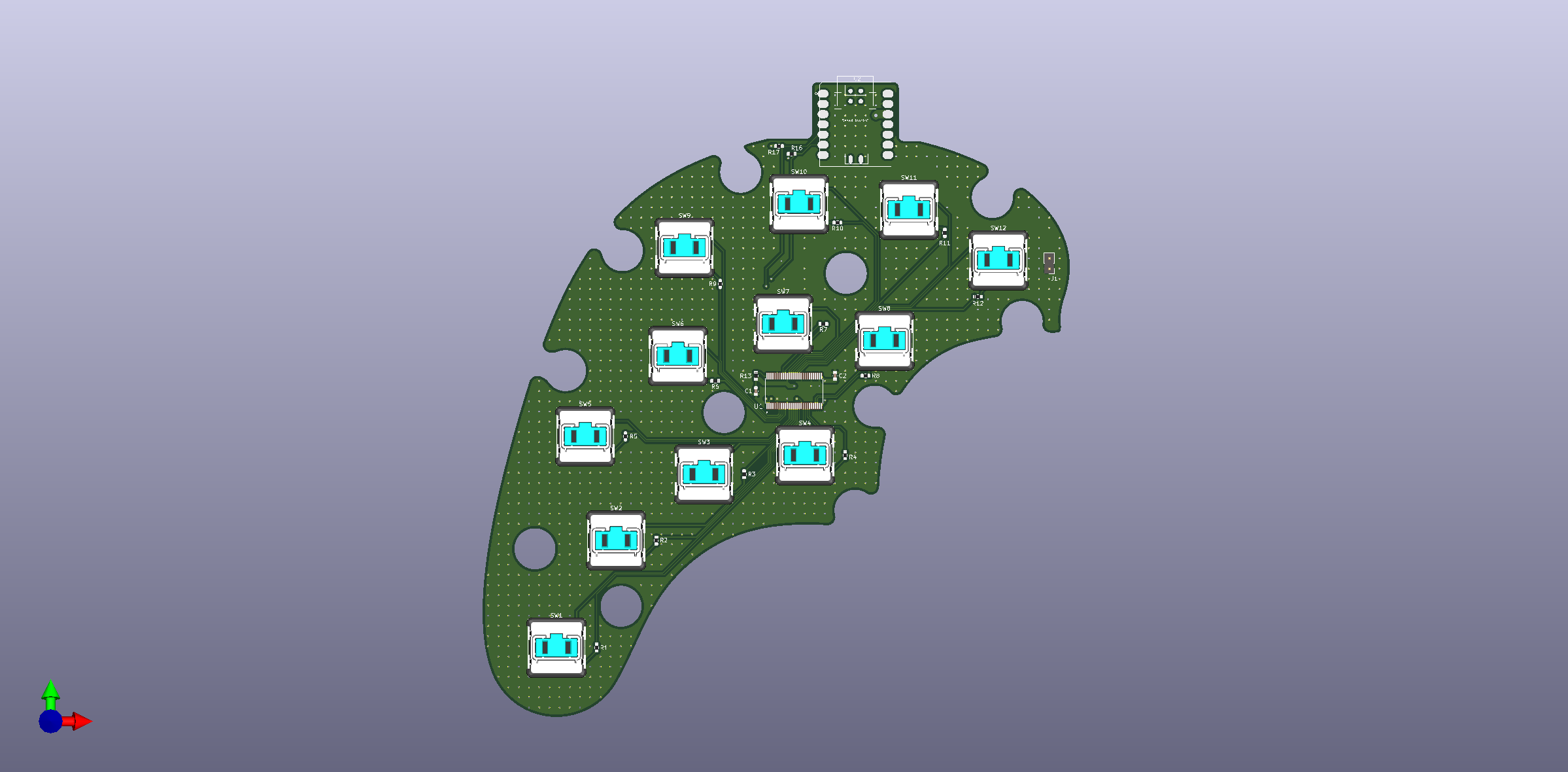

then I brought that into Solidworks to use it as a reference image to do some component layout to see what a finished macro pad would look like

Followed by many iterations of laser-cut & 3D Printed layouts to make iterative improvements

PCB design was severely limited by the current (2022) chip shortage. It was a fun challenge to design a PCB with heavy component selection constraints.

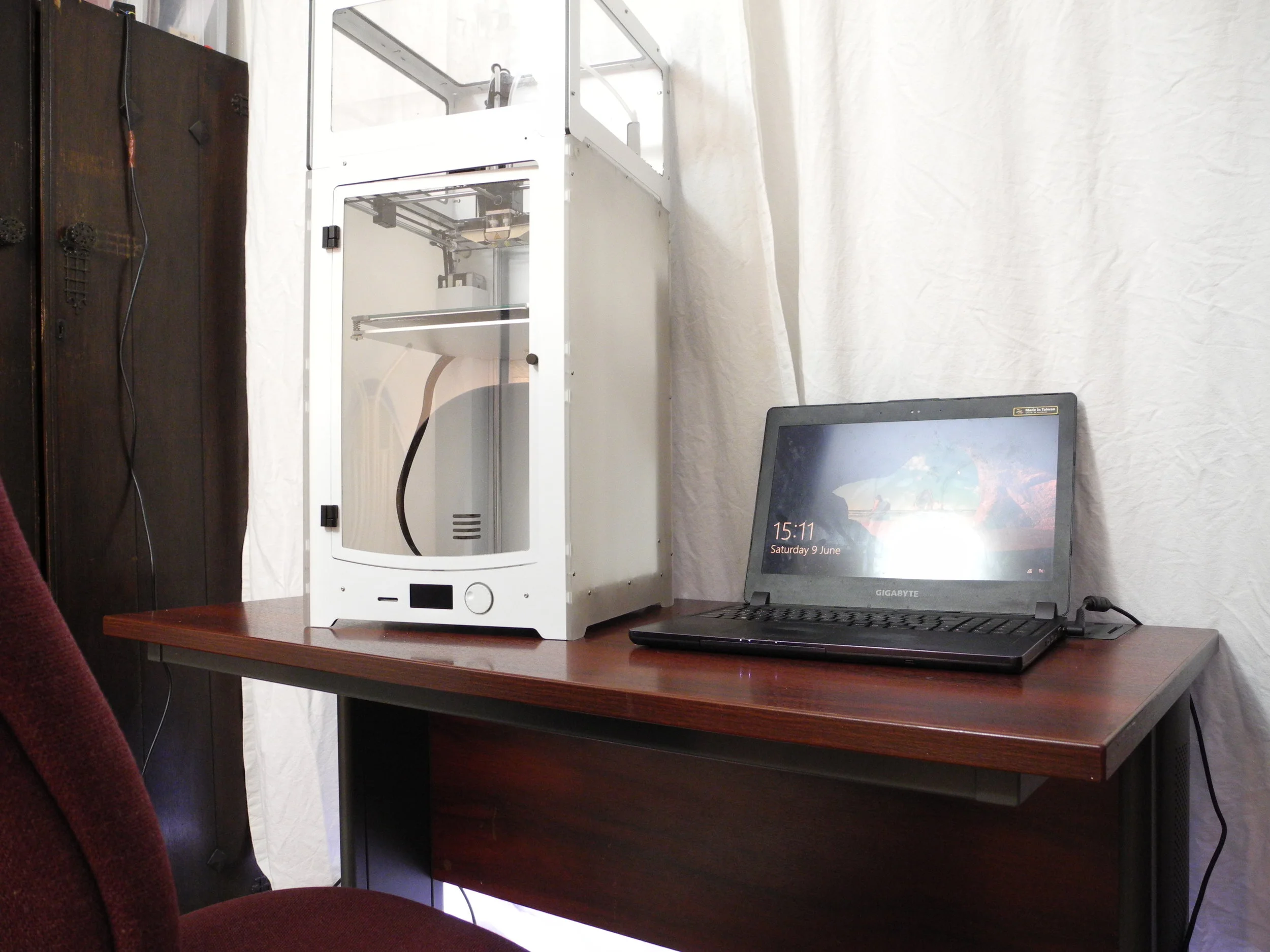

Completed Product

Here are some glamour shots of the finished item.

Future Work

Make the macro pad thinner by ~2mm

Replace the 3D Printed outer shell with a CNC machined and anodised part

Make power passthrough from Macro Pad to SpaceMouse

If you would like to build one ~> GitHub